المنتجات الساخنة

IOP Conference Series: Materials Science and Engineering

网页efficiency of the grinding process by providing an optimal motion mode of grinding media. Lining profile significantly affects the motion mode of the grinding media and the wear of

Contact

Consumption of steel grinding media in mills A review

网页2013年8月1日 Consumption of grinding media in mills is an economically important problem. • Current understanding of factors influencing wear loss of steel balls in mills is

Contact

Comparatives Studies Industrial Drum Mill RELO

网页2017年2月7日 A new working media for drum mills has been tested, composed of spheroidal tetrahedrons. The mass of the spheroidal tetrahedrons grinding media was

Contact

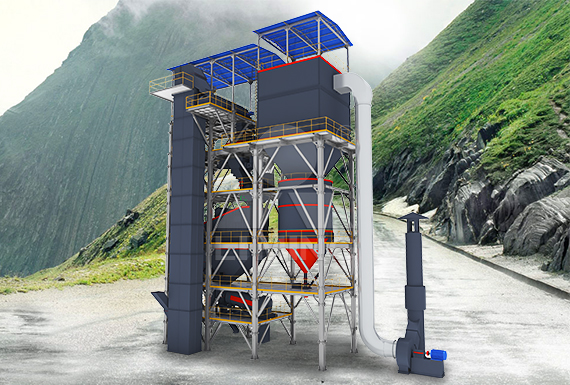

Drum mills by SIEBTECHNIK TEMA Comminution

网页Drum mills have a horizontal grinding drum rotating around a fixed center of rotation. Located in this cylindrical working space is a grinding-media

Contact

The Power Consumption Calculation of a Ball Drum Mill

网页2019年8月2日 grinding. A material grinding process in ball drum mills is executed by grinding bodies that move in a transverse section of a mill drum. Besides, only 50% of

Contact

Grinding Media Growth Steel

网页1 天前 Grinding Media FORGED BY EXCELLENCE As an expert and leading manufacturer of grinding media, we pride ourselves on their performance and quality. Manufacturing is our craft providing

Contact

Grinding Media Union Process

网页Grinding MediaGrinding Balls. Metallic Grinding Media; Non-Metallic Grinding Media; Grinding media, the objects used to refine material and reduce particle size, are available in a wide range of shapes, sizes and

Contact

Stirred media mills in the mining industry: Material

网页2020年6月1日 This review describes stirred media mill technologies and operating principles, and summarises stress intensity theory which can be used for selecting

Contact

(PDF) Grinding Media in Ball Mills-A Review ResearchGate

网页2023年4月23日 Grinding Media in Ball Mills-A Review Authors: Nyasha Matsanga Willie Nheta Ngonidzashe Chimwani Abstract and Figures Comminution is a very important

Contact

Largest selection of grinding media Glen Mills, Inc.

网页2023年1月24日 Rare Earth stabilized Zirconium oxide Grinding Media (sp.gr. 5.8 to 6.1) ZrO2 + CeO. Yellow or black, very hard. Sizes from 400 microns to 2″. Medium cost.

Contact

Grind Molycop

网页2023年7月1日 With a wear performance up to 25% longer than the standard High Carbon Grinding Rod, the HTR50 has outstanding resilience and a hardness profile that has a high surface hardness and lower

Contact

Open Access proceedings Journal of Physics: Conference

网页2023年2月27日 As a result of the research it was established that the character of the dynamic impact of the grinding media in the mill drum is significantly influenced by the mutual arrangement of the EED both in the The rational scheme of the installation of the EED in the drum mill with the grinding of materials pre-crushed in PRG is the scheme in

Contact

Experimental study of clinker grinding in a ball mill and the

网页2022年8月18日 For the drum filled with 6% of grinding media filling degree, the spheres presented a different behavior, since there is not a drop, but a rolling among the grinding media when the mill completes its cycle. This explains the lower collision forces in this case, corroborating with the results presented in Table 4 for the rotation speed of 15 rpm.

Contact

Experimental study of clinker grinding in a ball mill and

网页2023年6月27日 Using DEM, the numbers and intensity of the collisions between the grinding media and the mill walls were evaluated, along with the drum ow regime. It was compared then, the eects of the variables obtained drum volume and lling degree of grinding balls was kept to 4% of the drum capacity. In the second design, clinker lling

Contact

Ball Mill an overview ScienceDirect Topics

网页Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

Contact

US20110297775A1 Grinding media Google Patents

网页Grinding media for fragmentation and grinding of ores, rock and earth mass and other materials mostly in drum mills, for application in ore mining, construction and other industrial branches. The grinding media have the form of spheroidal tetrahedron, obtained from the crossing of four spheres with equal radii, the centers of each one lie on the top of the

Contact

TM 300 Drum Mill Glen Mills, Inc.

网页2022年4月18日 TM 300 Drum Mill. The TM 300 Drum Mill is used for the preparation of granules and powders. The grinding process is performed either in dry or wet conditions. The drum mill can be operated either as a

Contact

Construction of the electromagnetic mill with the grinding

网页2016年1月1日 Conventional grinding of mineral raw materials is carried out by material removal by the grinding media. In the classical drum mills – ball or rod – the movement of the grinding media is caused by the rotation of the cylindrical working chamber filled with grinding media. A disadvantage of such mill is a high energy consumption

Contact

The Power Consumption Calculation of a Ball Drum Mill

网页2019年8月2日 grinding. A material grinding process in ball drum mills is executed by grinding bodies that move in a transverse section of a mill drum. Besides, only 50% of grinding bodies grind a material, and the remaining 50% are dead zones- do not grind a material. An intensification of grinding media movement enables to improve an efficiency

Contact

For fine and ultra-fine grinding SIEBTECHNIK TEMA

网页2020年5月20日 Discontinuous operated drum mills make, in addition to size reduction, homogenization of the material to be ground possible. Application Drum mills have a horizontal grinding drum rotating around a fixed center of rotation. Located in this cylindrical working space is a grinding-media filling, which is tumbled by the rotating grinding drum.

Contact

A Comparative Study of Energy Efficiency in Tumbling Mills

网页An evaluation of Relo grinding media (RGM, Reuleaux tetrahedron-shaped bodies) performance versus standard grinding media (balls) was made through a series of grinding tests, including a slight modification of the standard Bond test procedure. Standard Bond tests showed a reduction in the Bond ball mill work index (wi) of the mineral sample used

Contact

(PDF) Improving the efficiency of the coal grinding process

网页2022年2月24日 Improving the efficiency of the coal grinding process in ball drum mills at thermal power plants. the load factor of the grinding media ranges from 0.325 up to 0.335, the supplied air velocity

Contact

Solids and powder milling Size reduction

网页2022年7月31日 Mills with size reduction media: Ball mills (dry) Ball mills are basically made of a drum partially filled with a grinding media, typically beads of ceramics or steel. The mill is filled with the grinding beads as

Contact

Roller Press KHD Humboldt Wedag

网页Simply put, the roller press is the most energy-efficient grinding machine on the market. Since its commercial introduction into the cement industry by KHD in the 1980s, hundreds of them have been installed in the cement

Contact

2022/sbm grinding ball drum.md at main naicha22/2022

网页Contribute to naicha22/2022 development by creating an account on GitHub.

Contact

(PDF) Monitoring of grinding condition in drum mills based

网页2022年11月9日 media m t = 8 t; ore density 2,800 kg/m 3; density of grinding media 7,800 kg/m 3. Duration of simulation w as 35 s with simulation step 0.0005 s. Drum r otation speed s were se-

Contact

Discrete-element simulations of comminution in rotating drums

网页2020年2月5日 By means of Discrete-Element simulations with Bonded-Cell method for particle breakage, we investigate the evolution of crushable granular materials in a 2D rotating drum partially filled with heavy balls and powder grains. The grinding process with balls of different sizes or numbers is analyzed in terms of grain size and specific surface.

Contact

_Taurus Ball Mill NETZSCH GrindingDispersing

网页1 天前 Ball Mill for Fine and Ultrafine Products. NETZSCH Ecutec's Taurus has the most advanced technology in Mills using Grinding Media for micronizing. A rotating robust steel drum with liners is supplying kinetic

Contact

GrindingCrushing Mill VIBRA-DRUM®

网页VIBRA-DRUM® Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency. The features listed below highlight why our mills are so effective and efficient. Proven

Contact

WO2010094091A1 Grinding media Google Patents

网页The present invention relates to grinding media for fragmentation and grinding of ores, rock and earth mass and other materials mostly in drum mills, and it finds application in ore mining, construction and other industrial branches. The grinding media have the form of spheroidal tetrahedron, obtained from the crossing of four spheres with equal radii, the

Contact