المنتجات الساخنة

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

网页In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball

Contact

Analysis of material flow and consumption in cement

网页2016年1月20日 The material efficiency values for a raw mill, pyro-processing tower, rotary kiln, clink cooler, and cement mill are determined to be 36.69%, 34.24%, 39.24%,

Contact

GitHub

网页sbm weight of cement millsCalculate and Select Ball Mill Ball Size for Optimum Grinding In Grinding,selecting (calculate) the correct or optimum ball size that allows for the best

Contact

On The Mechanical Aspects Concrete Containing Mill Scale

网页2023年1月20日 effects of partial replacement of fine aggregate by mill scale in concrete in varying proportions by weight. Mill scale was added by weight of fine aggregate with

Contact

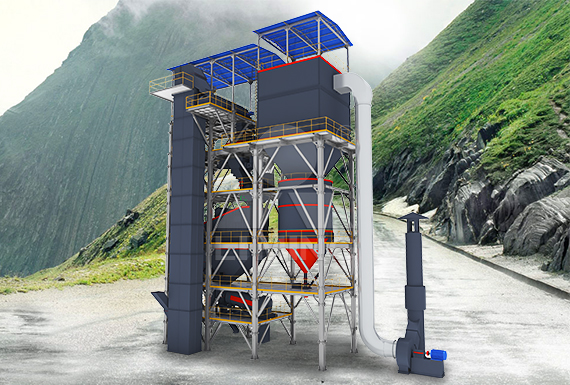

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement

网页Capacity: 13-70T/H. Vertica raw mill, also known as vertical roller mill, in the 1920s, the first vertical raw mill in cement plant is designed in German. It is widely used in cement,

Contact

Cement Ball Mill Cement Grinding Machine

网页Capacity: 33-85 t/h SEND INQUIRY What Is Cement Ball Mill The cement ball mill is a kind of cement grinding mill. It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding

Contact

Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

网页Cement mill also called cement grinding mill, is a cement grinding machine used in cement plant for raw materials, cement clinker, and coal grinding. The cement mill produced by

Contact

Cement Mill Notebook PDF Mill (Grinding) Steel Scribd

网页2023年2月22日 Mill through put (m): 18000 kg/h Radiation (q'') = 200 kcal/m2.h Clinker entrance temperature (Tki):15.0 C Cement leaving temperature (Tco): 95.0 C Average

Contact

Unit Weight of Construction Materials- Cement,

网页29 行 2019年9月11日 1760 to 2000 kg/m3. 4. Stone (Basalt) 2850 to 2960 kg/m3. 5. Cement Concrete (Plain) 2400 kg/m3. 6. Cement Concrete.

Contact

Stacker And Reclaimer Cement Plant Parts

网页The stacker and reclaimer is the pre-homogenization system in the cement plant.As a necessary part of the cement production line, it can concurrently or respectively complete the stacking and reclaiming. The stacker and

Contact

Raymond Mill, Raymond Mill For Sale Cement

网页Feeding Size: ≤15-≤30mm. Application: powdering calcium carbonate, gypsum, non-metallic ore and coal, desulfurizing work in power plant. get price! Raymond mill is a common cement mill of cement plant, and

Contact

(PDF) IMPROVING PRODUCTIVITY BASED ON THE

网页2019年12月25日 Illustration of the cement mill Z1 in kufa cement plant. The grinding process in the first compartment when producing O.C. according to (Powell and McBride, 2004 and Katubilwa, 2008).

Contact

(PDF) Effects of Mill Speed and Air Classifier Speed on

网页2021年6月29日 Optimum performance of ball mill could potentially refine Blaine fineness, thereby improving the cement quality. This study investigates the effects of separator speed and mill speed on Blaine

Contact

Ventilation Prediction for an Industrial Cement Raw Ball Mill

网页2021年6月10日 In cement mills, ventilation is a critical key for maintaining temperature and material transportation. However, relationships between operational variables and ventilation factors for an industrial cement ball mill were not addressed until today. This investigation is going to fill this gap based on a newly developed concept named “conscious laboratory

Contact

Cement Mill Liner EB Castworld % Cement Mill

网页Cement Mill Liner Special Features : We make Cr-Mo Alloy steel and high Cr white iron castings with Sodium Silicate Sand Process and Resin Sand Process. Our supply finished alloy steel castings with heat-treatment and

Contact

Analysis of material flow and consumption in cement

网页2016年1月20日 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system. 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages; waste gases

Contact

Vertical Roller Mills

网页Vertical roller mills offer supreme grinding with high energy-efficiency. Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition

Contact

(PDF) Cement plant operation handbook Academia.edu

网页The purpose of this study is to evaluate performance cement of production and cement kiln. The design of energy efficient dryers employing heat pump systems and the dynamic response of the product to the kiln conditions must take into account. In this , the formulation of a dynamic and kiln-wide drying model is described.

Contact

Conversion of Mill Scale Waste into Valuable Products via

网页2015年6月1日 Mill scale is one of waste materials which is produced as a result of hot rolling of steel in all steel companies. On the other hand, mill scale is considered a rich iron source with minimum impurities. This work aims at conversion of mill scale by adjusting smelting processes to produce different valuable products. The smelting processes were

Contact

All Pakistan Cement Manufecturars Association

网页2021年4月5日 Cement milling. The cement mills use steel balls of various sizes to grind the clinker, along with a small quantity of gypsum to a fine powder, which is then called cement. maximum contents of chlorides

Contact

Raymond Mills Raymond Roller Mill Grinding Mill AGICO Cement

网页Raymond mill is also called Raymond roller mill. It is a new type of high-fineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball mill.This kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc. Under normal conditions, these materials’ Mohs

Contact

(PDF) Dust Emission Monitoring in Cement Plant Mills: A

网页2021年8月28日 the bag filter at the outlet of the cement mill and the stack after the bag filter at the outlet . 7.98 mg/Nm 3 for 2020, with a weight approximately equal in the year 2019 and slightly .

Contact

A novel self-learning fuzzy predictive control method for the cement

网页2023年4月1日 3.2. Working condition analysis. The main factors affecting cement strength include: cement fineness, clinker ratio and clinker quality. The rotate speed of the classifier determines the cement fineness, the steel ball load determines the grinding capacity of cement mill, and the clinker ratio is manually adjusted by experts after comprehensive

Contact

cement mill_cuiy0060的博客-CSDN博客

网页2013年10月9日 The cement manufacturing process consists of many simultaneous and continuous operations using some of the largest moving machinery in manufacturing. Company Name: Henan Zhengzhou Mining Machinery Co., Ltd. 24-hour Free Sales Consulting Phone : 861-0371 -5590 2866 . Company Address: Qiaolou caizhai industrial

Contact

Cement Manufacturing Machine Cement Making

网页A cement mill is just a general term for clinker grinding mill. It is a kind of grinding equipment that used to grind the calcined cement clinker then make them reach the particle fineness requirement of the finished cement

Contact

Fishing ToolsServices Catalog SLB

网页2022年4月8日 Conductor Taper Mill Cement Mill.. 26 Taper Mill Hydraulic anchors eliminate need for drill collar weight to achieve backoff Tool generates up to 60,000 ft.lbf Tool design eliminates need for overtorquing

Contact

BULK MATERIAL DENSITY TABLE Tapco, Inc

网页2018年3月22日 Cement, Clinker 75-95 Cement, Rock (See Limestone)-Cement, Portland 94 Cement, Aerated (Portland) 60-75 Cement, Mortar 133 Chalk, Crushed 75-95 Mill Scale 120-125 Milo 40-45 Milo, Ground 32-36 Molybdite, Powder 107 Mortar, Wet 150 Muriate of Potash (See Potash Muriate)-Mushrooms 24 Mustard Seed 45

Contact

Coiled Tubing Solutions OilProduction.net

网页2016年3月18日 used in combination with a 3.35 in. turbo mill. This system was chosen because of the plug form of the cement. Result: The underreamer used in combination with the turbo mill successfully milled 1,118 ft of cement in a single run. Using water and high viscous pills, an average rate of penetration (ROP) of 74.50 ft/hr was achieved. Well

Contact

(PDF) DYNAMIC DESIGN FOR GRINDING MILL

网页2019年1月30日 Motor weight is 62,200 kg, two motors in the fixed bearing end, operating at speed 180 rpm. The concrete mill foundation is modelled using solid element with dimension of 0.91 x 0.91 x 0.91 m as .

Contact